NEWS

WORKING TOGETHER

TRUMPF machine installing

We are proud to announce the successful installation of a TRUMPF CO₂ laser machine at one of our customer’s factories. This advanced machine enhances precision cutting capabilities, ensuring high efficiency and top-quality results for the customer’s production line.

Our skilled installation team carefully handled every step of the process, from site preparation to final calibration. The machine was set up with precision, ensuring optimal performance and seamless integration into the customer’s workflow. After thorough testing and operator training, the machine is now fully operational and delivering excellent results.

Repairing fire accident damage to TRUMPF laser machine

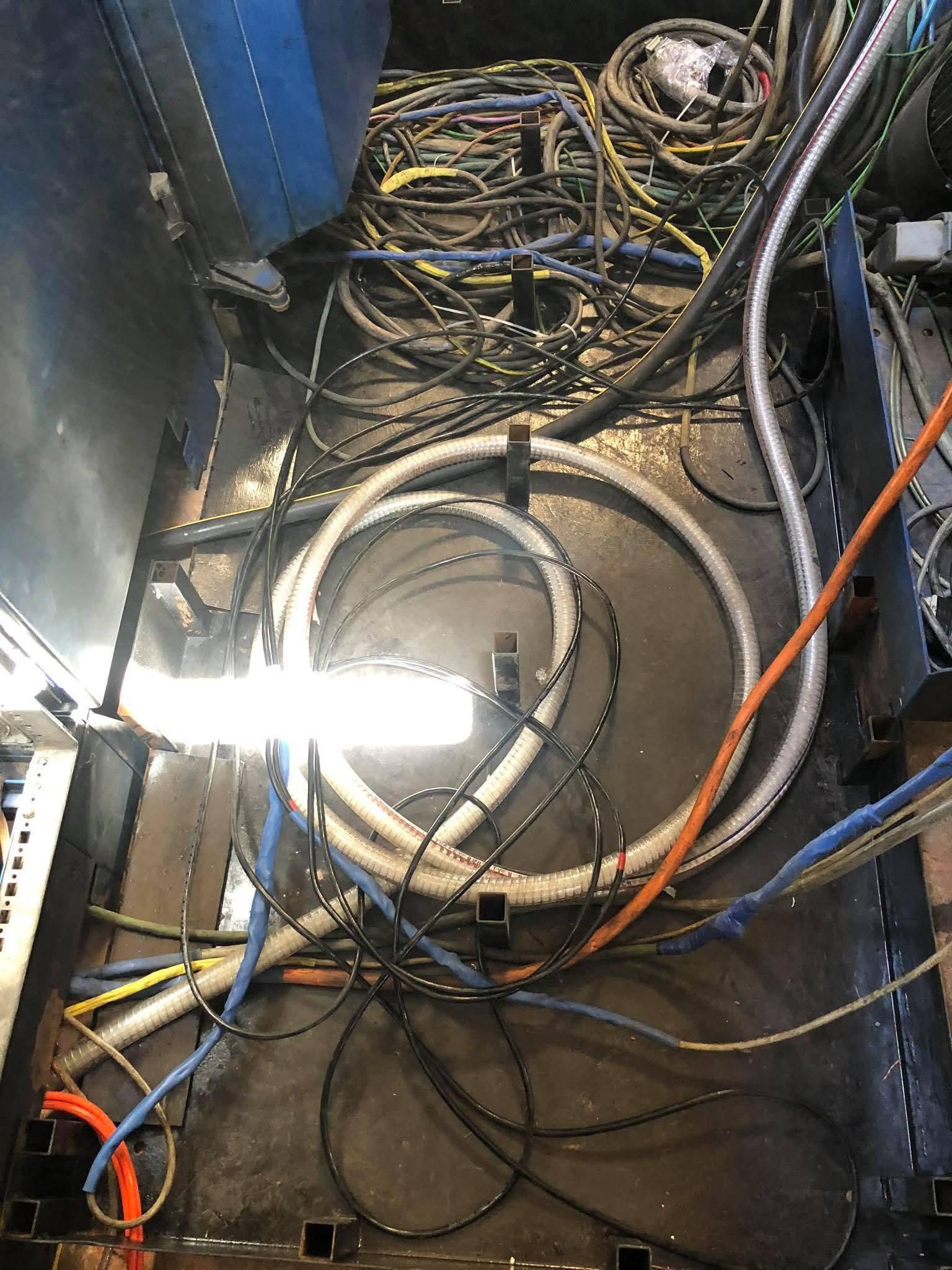

A recent accident at one of our customer’s factories resulted in severe damage to the main electrical cables of their TRUMPF laser machine due to a fire. This unexpected incident threatened to halt production for an extended period.

Our expert maintenance team responded swiftly, replacing all damaged cables and resolving every issue efficiently. Thanks to their dedication and expertise, the machine was fully restored and back in operation in record time, minimizing downtime and ensuring our customer’s business continuity.

End of Year LSC's Party (15-1-2025)

On January 15, 2025, our company hosted a grand appreciation event to honor our valued clients and dedicated employees. The evening was filled with gratitude, recognition, and celebration of loyalty and hard work. As a special surprise, we held a thrilling lottery, awarding one lucky customer a fully paid Umrah trip. This event reaffirmed our commitment to strengthening relationships and expressing heartfelt appreciation to those who contribute to our success.

The lottery was drawn and Eng\ Tariq Shamloul won the Umrah trip !

TRUMPF machine board replacement & software installing

Rather than replacing an entire industrial computer, our team successfully restored full functionality by replacing only the motherboard.

This smart and efficient solution significantly reduced costs for our client while ensuring seamless operation.

Our expertise in TRUMPF and SIEMENS PCU 50 SINUMERIK 810D/840D systems continues to deliver reliable and cost-effective maintenance solutions.

TRUMPF machine installation

We are pleased to announce the successful installation of another TRUMPF CO₂ laser machine for a valued customer. This state-of-the-art machine enhances production efficiency, delivering precise and high-quality cutting performance.

Our experienced team managed the entire installation process, ensuring seamless setup and integration. From electrical connections to system calibration, every step was executed with precision to guarantee optimal performance. After final testing and operator training, the machine is now fully operational and ready to support the customer’s manufacturing needs.

Precision

Accuracy

Quality

Time

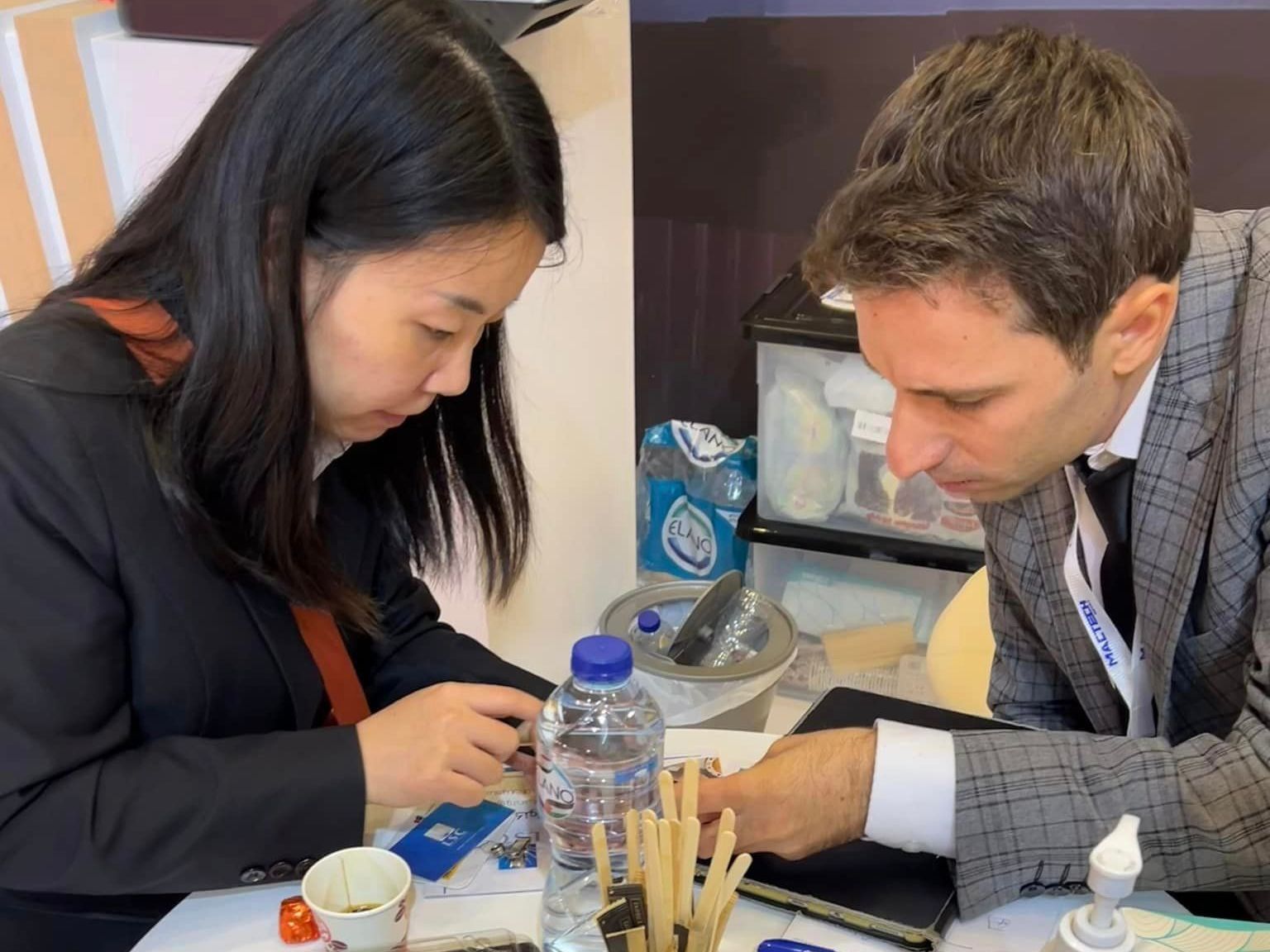

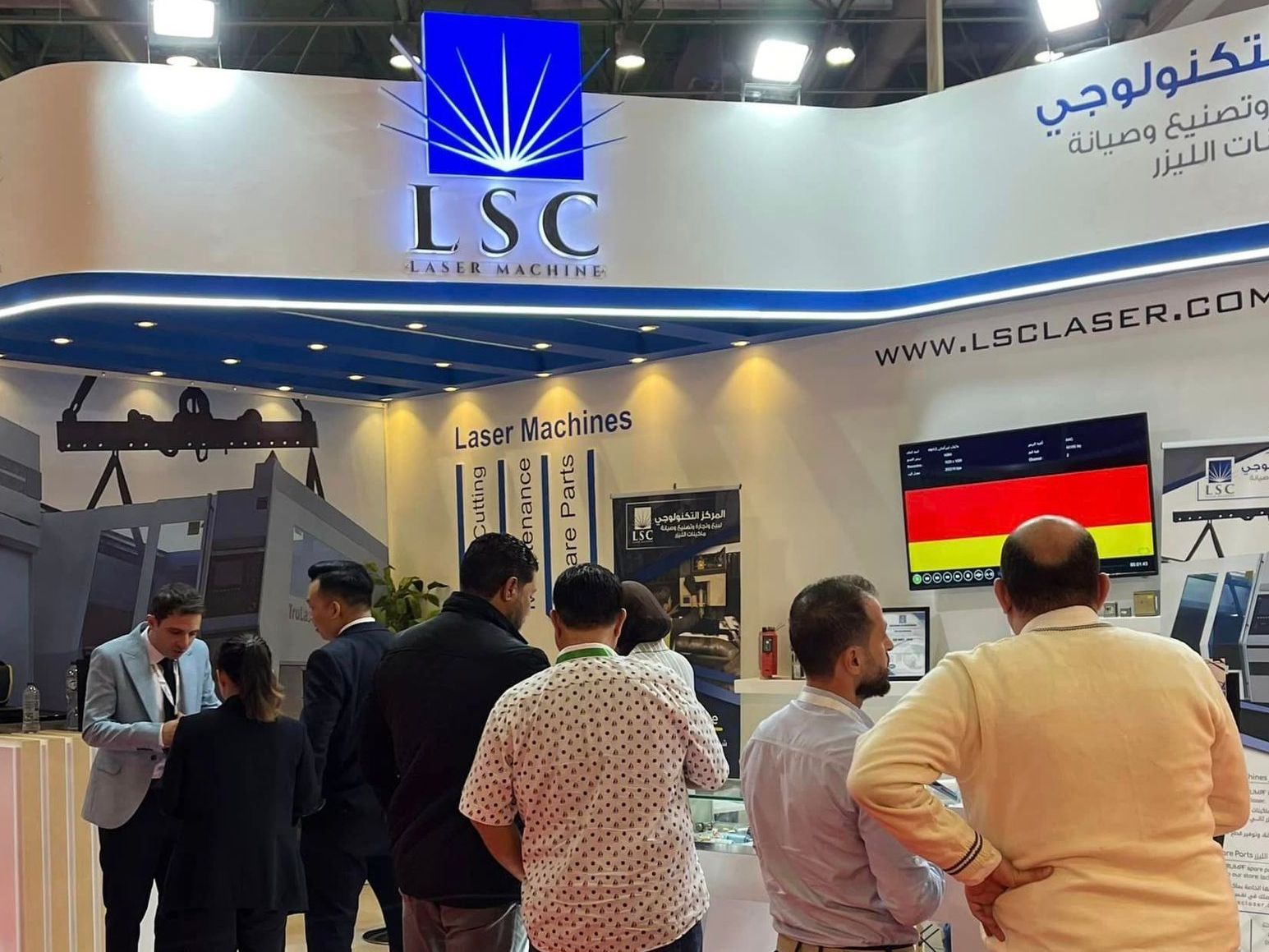

Participation in MACTECH Egypt 2024 Exhibition (12-15 DEC 2024)

From December 12 to 15, 2024, we proudly took part in the MACTECH Egypt exhibition, the region’s leading event for industrial and manufacturing technologies. Partnering with Dar El Handasa (EHI), we showcased cutting-edge innovations as the exclusive representative of ZPG Laser Machines Global, a renowned Chinese manufacturer. Our presence highlighted the latest advancements in laser technology, reinforcing our commitment to delivering high-quality solutions to the industry.

MACTECH 2024 AWARD

We are honored to receive the MACTECH Participation Award in recognition of our strong presence and contributions at MACTECH Egypt 2024.

This achievement reflects our commitment to innovation and excellence in the industrial and manufacturing sector.

Partnering with

Dar El Handasa (EHI) as we are the exclusive representative of

ZPG Laser Machines Global, we showcased advanced laser solutions that set new industry standards.

This award motivates us to continue delivering cutting-edge technology and exceptional service to our customers.

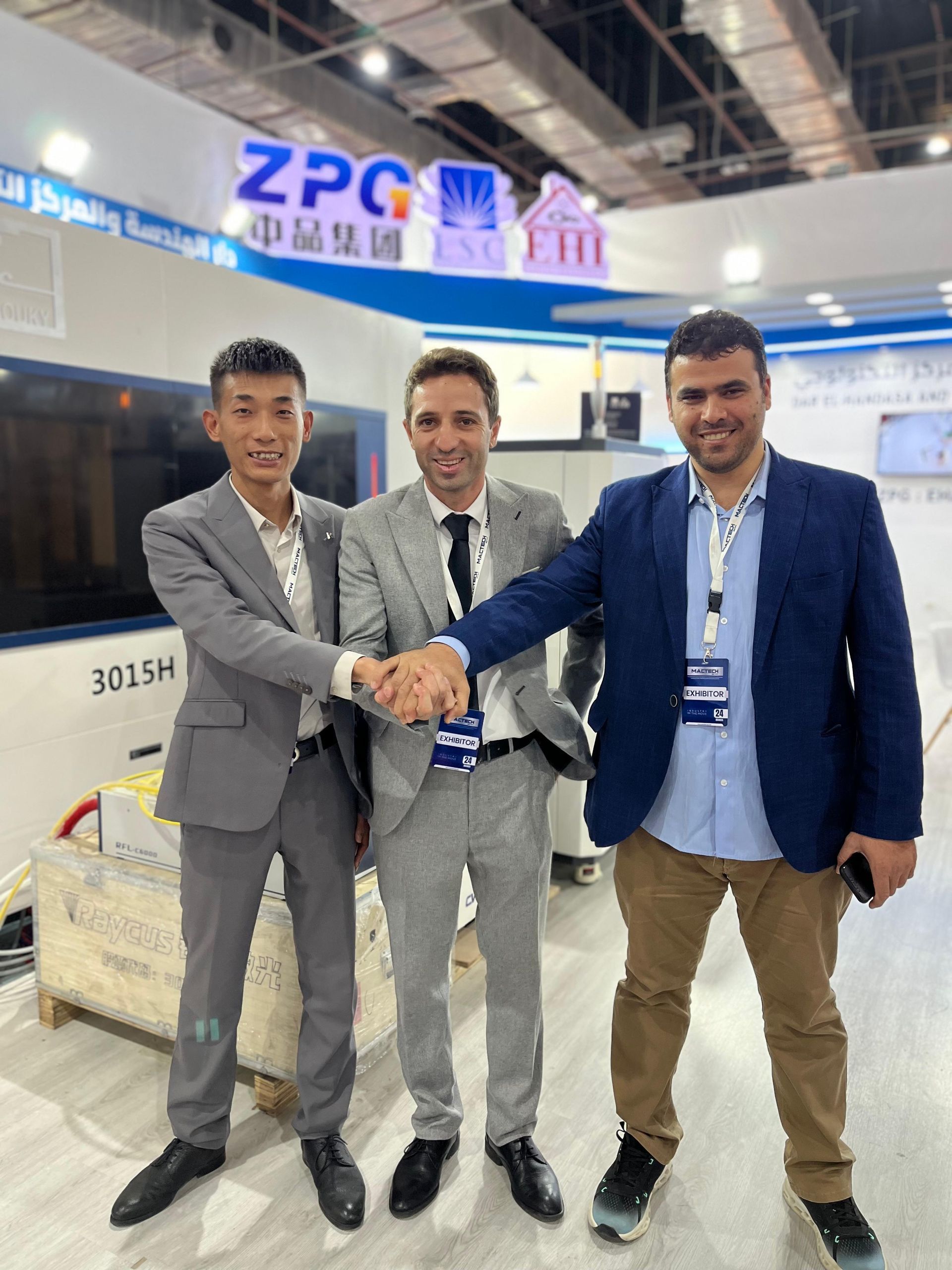

LSC Side by side with EHI & ZPG

Our collaboration with Dar El Handasa (EHI) and ZPG Laser Machines Global reflects a shared vision for advancing industrial technology.

Together, we bring state-of-the-art laser solutions to the market, combining expertise, innovation, and reliability.

This partnership strengthens our commitment to delivering high-performance machinery and exceptional service.

By uniting forces, we continue to set new benchmarks in precision, efficiency, and technological excellence.

Installation and renew TRUMPF machine

As part of our latest project, we successfully installed and renewed a TRUMPF machine (TruLaser 5040), restoring its full functionality and enhancing its efficiency.

Our expert team carried out a comprehensive refurbishment, including component upgrades, recalibration, and performance optimization.

This cost-effective solution extended the machine’s lifespan and ensured seamless operation, delivering maximum value to our client.

Our commitment to precision

and quality continues to drive successful industrial solutions.

Before & After !

Our products sold to every place in the world, even to Australia!

Our online store continues to serve customers across the globe, providing high-quality spare parts for TRUMPF and leading Chinese laser machine manufacturers.

Recently, we successfully completed a shipment to a customer in Australia, further proving our ability to deliver reliable solutions anywhere in the world.

With a commitment to efficiency, precision, and customer satisfaction, we ensure fast and secure international shipping, reinforcing our position as a trusted global supplier in the laser industry.

Mirror Cleaning

Regular maintenance is essential to keep TRUMPF laser machines operating at peak performance. Recently, our expert team provided a professional mirror cleaning service for one of our customers, ensuring their machine maintained optimal cutting precision and efficiency.

Over time, dust, debris, and laser residue can accumulate on mirrors, reducing laser power and affecting cutting quality. Our technicians carefully cleaned and inspected the mirrors using specialized tools and techniques, restoring them to perfect condition. After servicing, the machine's performance improved significantly, helping the customer maintain high productivity.

TRUMPF machine generator fixing

Our technical team has successfully completed the maintenance of a laser machine turbine, ensuring optimal performance and reliability.

This service covered comprehensive diagnostics, fine-tuning, and necessary repairs for both CO₂ and fiber laser resonators.

With our expertise in TRUMPF laser systems, we continue to provide top-tier maintenance solutions, maximizing efficiency and extending the lifespan of critical industrial equipment.

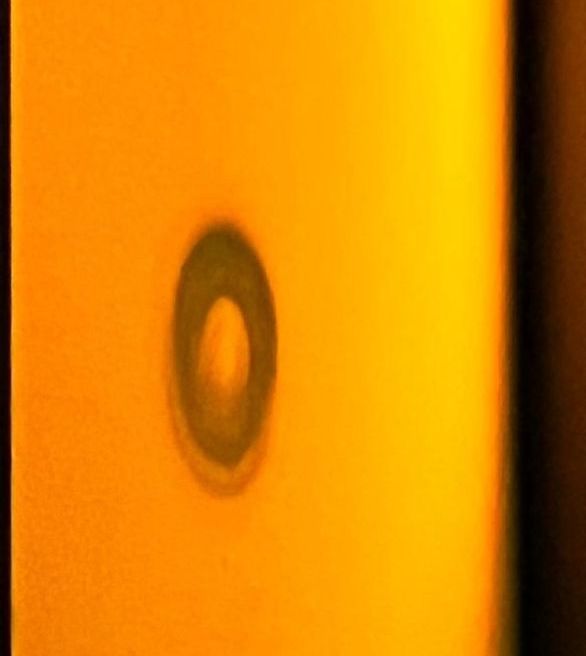

Laser Beam Mode

The quality of a laser beam plays a crucial role in the performance and precision of laser cutting and welding processes. One of the key factors affecting this is the laser beam mode, which determines how energy is distributed within the beam.

What is Laser Beam Mode?

Laser beam mode refers to the shape and intensity distribution of the laser beam. The most common mode in industrial laser applications is

TEM₀₀ (Transverse Electromagnetic Mode 00), which provides a highly focused, stable, and efficient beam for precise cutting and welding.

Why is Laser Beam Mode Important?

- Cutting Quality – A well-optimized beam mode ensures clean, precise cuts with minimal heat-affected zones.

- Efficiency – The right beam mode maximizes energy utilization, reducing power waste and improving productivity.

- Machine Performance – Maintaining a stable beam mode extends the life of optical components and enhances overall machine reliability.

Ensuring Optimal Beam Mode

Regular maintenance, including

mirror cleaning, lens inspection, and beam alignment, is essential for keeping the laser beam in optimal condition. Our team of experts provides professional maintenance services to ensure your TRUMPF laser machine operates at peak performance.

TRUMPF Machine maintenance

Our maintenance team has successfully replaced the Tube Power IS30 as part of our ongoing service for TRUMPF laser machines.

With precision and expertise, we continue to provide top-quality maintenance solutions, keeping industrial laser machines running at peak efficiency.

TRUMPF machine mirror fix and replacement

During a recent service, we discovered that a lens inside the head was damaged due to a poor carbon steel surface.

Our team promptly replaced the lens, thoroughly cleaned all affected parts, and replaced any additional components contaminated by the debris.

We also performed a full check of the beam alignment across all four corners and inspected the CP_FOCUS_COMB to ensure perfect calibration.

After completing these steps, the machine is now fully operational, running smoothly and efficiently.

| LSC Last Projects last quarter of 2023

As part of its interest in industry and large projects, LSC installed a German TRUMPF metal laser cutting machine in a factory in Egypt. LSC continues to provide its services in everything related to laser machines, including installation and training. Maintenance, spare parts and machines follow-up, in addition to metal cutting services and order special spare parts.

| Strategic cooperation agreement

LSC Laser company Signed a strategic cooperation agreement with Markrobotic Which is based in Istanbul at the end of November 2023.

Markrobotic is specialized company in the design, assembly and manufacturing of the industrial automated machines.

We are confident that this collaboration will open new opportunities and strengthen our position as leaders in the field.

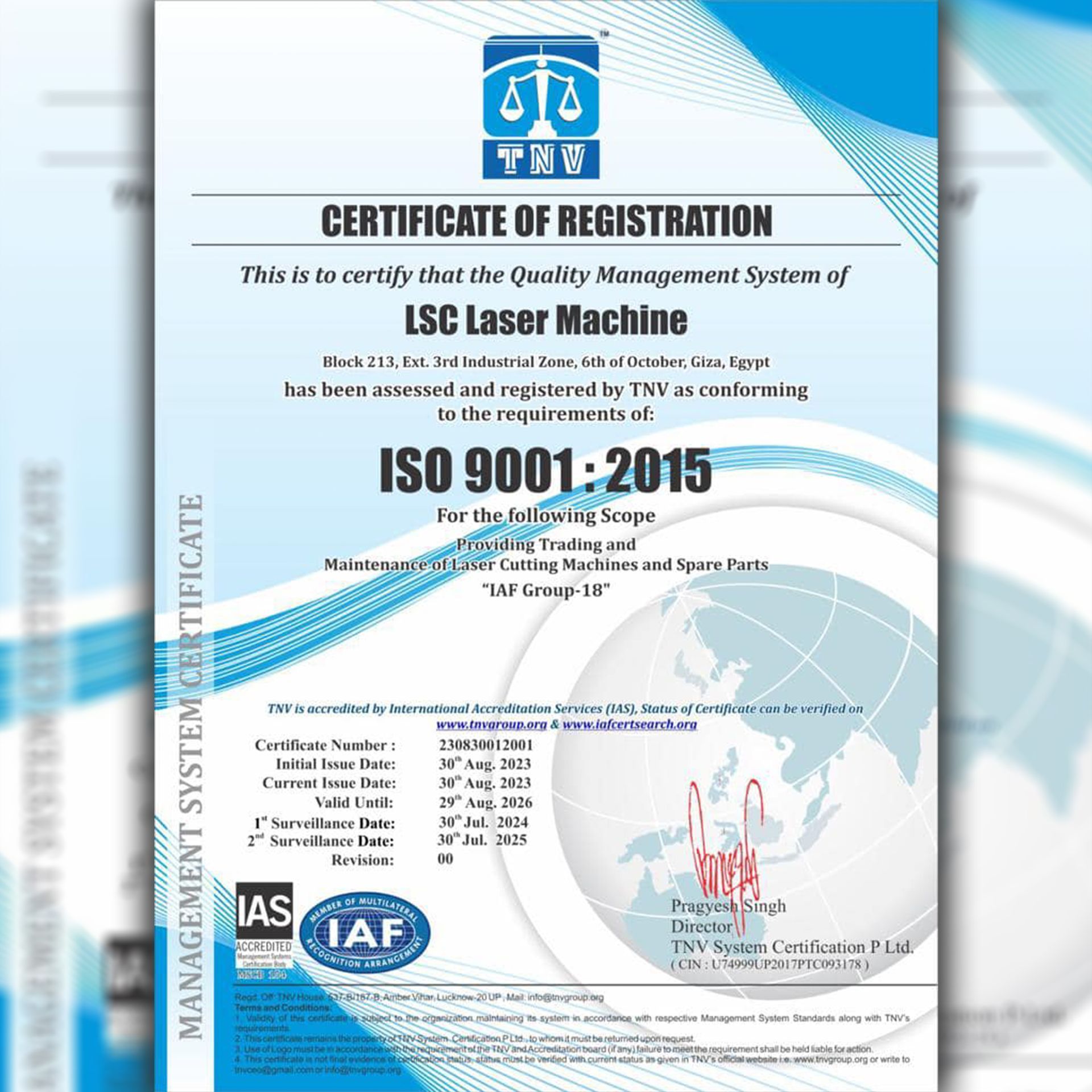

| LSC got the ISO quality assurance certificate

LSC got the ISO quality assurance certificate for its compliance with ISO requirements for 2015 year according to the following text: "Certificate of Registration tis is certify that the quality management system of LSC LASER has been assayed registered by TNV as conforming to the requirements of ISO 9001 : 2015 for the following scope: providing trading and Maintenance of Laser Cutting Machines and Spare parts “IAF Group-18”".

After this news, LSC posted on its official page on the Facebook platform that they thanks all the company’s employees and all the partners who helped to achieve this.

Every great work has a great beginning!

Interested in our NEWS?

You will find us active

on social media platforms

You can find us on:

Click on Icon to follow